We are a professional manufacturer of fishing hook machines for 8 years, including steel wire drawing machine, steel wire straightening and cutting machine, automatic grinding machine, steel wire dividing and cutting machine, automatic fishing hook forming machine and screw rod made with stainless steel, fishing hook shank flattening machine, automatic knife grinder for fishing hook, etc. Based on this and after years of development, combining with the practice of customer applications, a new generation of fishing hook machinery and equipment, including grinding machine, steel wire dividing and cutting machine and hook forming machine, have been formally launched.

The grinding machine is for the water mill type. When grinding, it does not cause any dust and is favorable to the operator's health. It also does not lead to high temperature ( water-cooled), thus will not change the molecular structure of the point. So after heat-treatment, the hooks can keep overall consistency on hardness and toughness (fracture resistance). The speed of the pinch roller can be adjusted at will. Synchronous adjusting apparatus front and back is used in the panel of the machine.

To overcome the tip collision and bending using traditional machines with chain and screw to transmit the wire, the new steel wire dividing and cutting machine employs roulette to send wire. The wire are cut when aligning the baseline without any pressure and resistance. The incision is smooth and the tip is sharp. Every detail reflects quality!

The new automatic hook forming machine still employs screw rod to transmit the wire. The screw uses stainless steel and with non-stop centromere. The bottom of wire slot is at a vertical section of a 90-degree angle ( when transmitting on the 2 screw rods, the wires are without any shaking), thus to ensure the accuracy of the relevant station in the forming of the hook, especially when moulding the blood trough hook point. The hook forming machine, using screw rod with non-stop centromere, is more easier and faster to adjust, for there is 1/2 circle turning for a pause time.

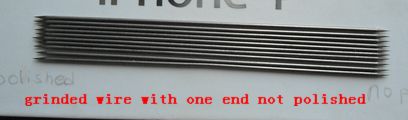

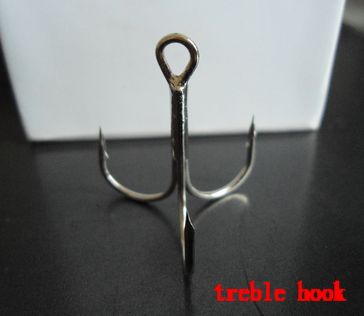

As can be seen from the pictures that the two-end grinded wire samples, there is one end without polishing and the tip also does not change the color with high temperature. Wires produced by dividing and cutting machine are at the same length, with sharp point and smooth incision. Hook samples are those blood trough hook with sharp and beautiful tip.

Our factory also supply the hand-welding equipment for treble hooks, with Japanese technology, easy to install and unload, and high precision when working.

In addition, we can provide customization for the following machines:

1. fishing hook shank flattening machines for especially small hooks with minimum wire diameter 0.2mm and unlimited hook height;

2. grinding machine for short wire length from 18mm to 20mm;

3. steel wire straightening and cutting machine for especially minimum wire diameter 0.1mm.